GDW Rhodius KMS –

World Market Leader in Engineering-Grade Knitted Mesh

- Leading in Separation, Industrial, and Safety Technology

- Highly efficient separation solutions

- Solutions for every standard and special application

- Quality "Made in Germany"

Technical Knitted Mesh and Separation Technology,

Industrial and Safety Engineering

In the fields of technical knitted mesh and separation technology, industrial and safety engineering, we are among the leading providers of separation products and filter modules.

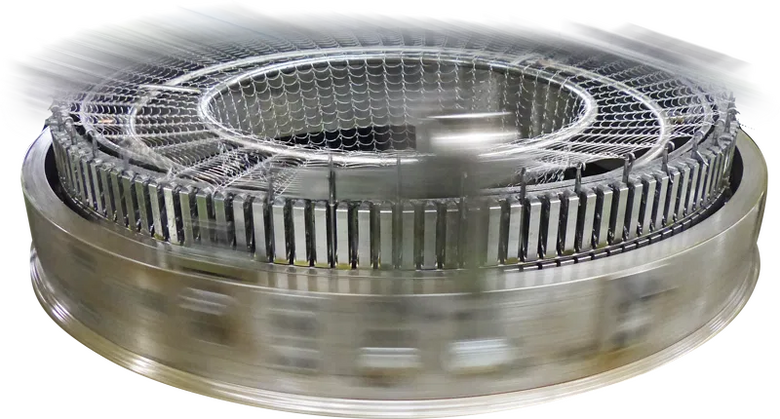

knitted mesh & separation (kms) develops and produces highly efficient separation solutions based on knitted mesh and fine fiber materials.

We offer demisters and filter cartridges for every standard and special application. Our meshes can be produced in almost any geometry, allowing for optimal fit tailored to each application. In addition to wire diameter, we precisely adjust material and density to match customer and process requirements.

Portfolio of GDW Rhodius KMS

From highly efficient separation solutions to essential components for electrolyzers – our products set standards.

Discover our core competencies. You'll find the perfect solution, precisely tailored to your process requirements.

Your Product in Three Steps

Consultation and

Needs Analysis

Together with you, our experts analyze your individual process requirements. If needed, we perform measurements in our technical center or directly at your site to create the ideal foundation for your custom solution.

Planning and

Proposal

Based on the analysis, we design your product using our proprietary software “Separate.” You will receive a transparent quote, including all relevant metrics such as separation efficiency and pressure drop.

Installation and

Support

Our experienced engineers can assist with installing your components directly at your facility – worldwide. We supervise the assembly team and ensure everything fits perfectly, even in unforeseen circumstances.

Why Companies Trust GDW Rhodius KMS

Custom Engineering

Solutions

From design with our in-house software “Separate” to production on machines developed by our own mechanical engineering team – we create tailor-made solutions for both individual parts and large series.

Quality

Made in Germany

At our site in Weißenburg (Bavaria), we ensure top product quality through strict controls. Our in-house mechanical engineering provides maximum flexibility and manufacturing that meets the highest standards.

Unmatched

Expertise

Benefit from 100 years of knitting experience! In 1970, we laid the foundation for our leading role in separation technology by producing our first demisters – today, we are the global market leader for knitted wire mesh.

Comprehensive Service & Support

Our service doesn’t end with delivery: if requested, our experienced engineers will assist with installation on-site – anywhere in the world.

Looking for a secure job with prospects in a great team?

Do you want to support our strong team with your commitment, enjoy your work, and inspire our customers?

Then you’re a perfect fit for us. Apply today – we look forward to meeting you and say “Welcome!”

Frequently Asked Questions (FAQ)

What exactly does GDW Rhodius KMS produce?

We are one of the leading providers of technical knitted mesh and separation technology.

Our core products made of knitted mesh include highly efficient separation solutions such as demisters and filter cartridges, pressed parts for the automotive industry, seals, and elastic elements for electrolysis applications.

Can I get a custom solution for my specific problem?

Yes, absolutely. Custom solutions are our specialty. We tailor material, density, and geometry precisely to your process requirements and develop the optimal solution with you – from one-off production to large-scale manufacturing.

Which industries are GSW Rhodius KMS’ products suitable for?

Our products are used in many industries. Key sectors include the automotive industry, mechanical and plant engineering, environmental and process technology, the oil and gas industry, the food industry, and the rapidly growing hydrogen and chlor-alkali electrolysis markets.

What materials are the meshes made from?

We process a wide range of materials. These include all common stainless steels, special materials such as nickel or titanium and their alloys (e.g., Monel and Inconel), various plastics from PP to PFA, and fiber materials like glass or carbon fiber.

How do I start a project or get a quote?

The easiest way is to send us your inquiry. Our experts will personally get back to you within 24 hours to discuss your requirements and initiate the next steps.